HVAC RENTAL EQUIPMENT

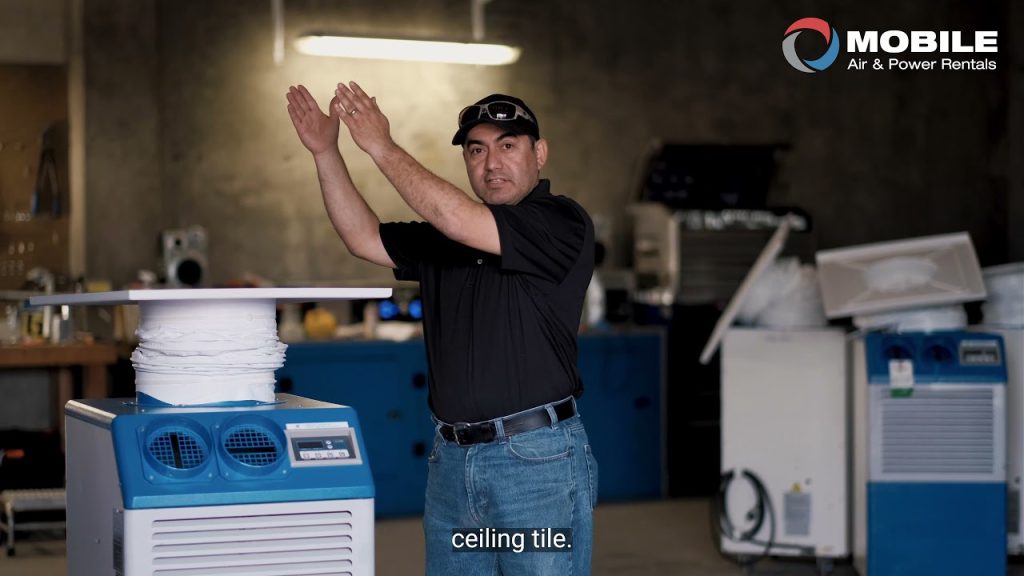

Mobile Air & Power Rentals provides portable cooling, heating, dehumidification, and power solutions. With our rental air conditioners, cooling towers, chillers, heaters, dehumidifiers, generators, and power distribution we can cover all of your temporary HVAC & Power needs.

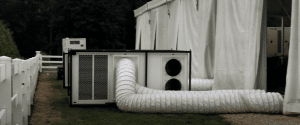

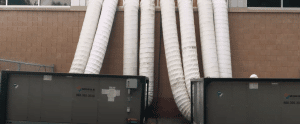

We offer a full line of units and customized solutions to fit your specific needs and environment. Our rental spot coolers are designed to fit through doorways and are easily wheeled into any space you need to be cooled. Our rental chillers and A/C units are trailer mounted and can be placed anywhere near a building or tent.

We offer multiple types of heaters; including electric, direct-fired, and indirect-fired rental heaters. Our direct and indirect-fired heaters are available in NG, LP, and diesel. We have 3 types of rental dehumidifiers available. Our rental power options include generators of all sizes and the power distribution needed for any situation.